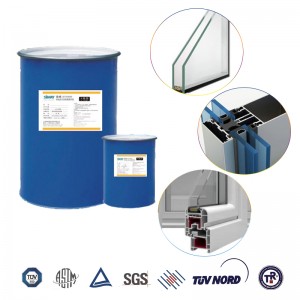

Sika Sikasil SG 500 Two-Component Silicone Adhesive

Short Description:

HIGH-PERFORMANCE, 2-COMPONENT SILICONE STRUCTURAL GLAZING ADHESIVE Sikasil® SG-500 S is a 2-component, high modulus, neutral curing structural silicone adhesive. This product is designed to be used in structural glazing applications.

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Sika Sikasil SG 500 Two-Component Silicone Adhesive, Welcome your visiting and any your inquires,sincerely hope we can have chance to cooperate with you and we can build up long well business relationship with you.

HIGH-PERFORMANCE, 2-COMPONENT SILICONE STRUCTURAL GLAZING ADHESIVE

Sikasil® SG-500 S is a 2-component, high modulus, neutral curing structural silicone adhesive. This product is designed to be used in structural glazing applications.

PRODUCT BENEFITS

1. Meets requirements of GB 16776, ASTM C 1184 and ASTM C 920 (class 25, movement capability ± 25 %)

2. Design tensile strength for dynamic loads: σdes = 0.14 MPa or 20 psi (ASTM) ▪ ▪ Adheres well to a wide range of substrates

3. Very good UV and weathering resistance

4. Good long term durability

AREAS OF APPLICATION

Sikasil® SG-500 S is used for structural glazing and similar high-demanding industrial applications. This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be performed to ensure adhesion and material compatibility.

TYPICAL PRODUCT DATA (FURTHER VALUES SEE SAFETY DATA SHEET)

| Properties |

|

||||

| Chemical base | 2-component silicone | ||||

| Color (CQP001-1) | mixed

|

|

|||

| Cure mechanism | Polycondensation | ||||

| Cure type | Neutral | ||||

| Density (uncured) | mixed

|

|

|||

| Mixing ratio | A:B by volumeA:B by weight | 10 : 113 : 1 | |||

| Viscosity (CQP029-6) |

|

||||

| Consistency | Paste | ||||

| Application temperature | ambient | 5 ─ 40 °C | |||

| Snap time (CQP554-1) | 60 minutes A | ||||

| Tack free time (CQP019-3) | 270 minutes A | ||||

| Shore A hardness (CQP023-1 / ISO 48-4) | 40 | ||||

| Tensile strength (CQP036-1 / ISO 527) | 1.9 MPa

|

||||

| 100 % modulus (CQP036-1 / ISO 527) | 1.0 MPa | ||||

| Elongation at break (CQP036-1 / ISO 527) | 270 %

|

||||

| Tear propagation resistance (CQP045-1 / ISO 34) | 2.7 N/mm | ||||

| Service temperature (CQP513-1) | -40 ─ 150 °C | ||||

| Shelf life |

|

| CQP = Corporate Quality Procedure | A) 23 °C / 50 % r. h. | B) storage below 25 °C |

Surface preparation

Surfaces must be clean, dry and free from grease, oil and dust. Surface treatment depends on the specific nature of the substrates and is crucial for a long lasting bond.

Application

The optimum temperature for substrate and sealant is between 15 °C and 25 °C.

Before processing Sikasil® SG-500 CN both components have to be mixed homogeneously and air-bubble-free in the correct ratio as indicated with an accuracy of ±10 %. Most commercially available metering and mixing equipment are suitable. For advice on selecting and setting up a suitable pump system, contact the System Engineering Department of Sika Industry.

Consider that the B-component is moisture-sensitive and must therefore only be exposed briefly to air.

Joints must be properly dimensioned.

Basis for calculation of the necessary joint dimensions are the technical values of the adhesive and the adjacent building materials, the exposure of the building elements, their construction and size as well as external loads.

Tooling and finishing

Tooling and finishing must be carried out within the snap time of the adhesive.

When tooling freshly applied Sikasil® SG-500 CN, press the adhesive to the joint flanks to get a good wetting of the bonding surface. No tooling agents must be used.

Removal

Uncured Sikasil® SG-500 CN may be removed from tools and equipment with Sika® Remover-208 or an-other suitable solvent. Once cured, the material can only be removed mechanically.

Re-usable, usually metallic, static mixer can be cleaned with Sika® Mixer Cleaner.

Hands and exposed skin have to be washed immediately using hand wipes such as Sika® Cleaner-350H cleaning towels or a suitable industrial hand cleaner and water. Do not use solvents on skin.

Overpainting

Sikasil® SG-500 CN cannot be overpainted.