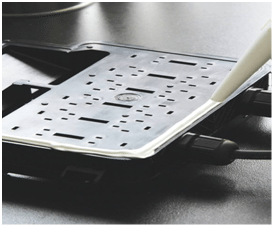

PV cells made from laminated glass or high performance plastics have to be bonded into aluminium housings before mounting into position. High grade industrial silicone adhesive is normally used to make a strong yet flexible bond between the two surfaces. Silicone adhesives have for many years been used in similar applications throughout the building and construction industry. They are now proven to withstand the continual changes in temperature caused by the heating up and cooling down of exposure to sunlight. As the two materials have different coefficients of expansion, the flexible nature of the cured silicone will absorb the movements without causing stress to the cell. Resistance to the detrimental effects of UV light is another reason to use a silicone adhesive.

Although some choose to use the traditional Acetoxy grade silicone sealants, this is not recommended due to the corrosive nature of the acetic acid by-products given off during the curing process. Many other building grade sealants use Oxime cured silicones as they are considered to be a very low corrosive material; they do however, carry some health and safety issues.

Siway sealant have developed a new generation of industrial/electronic grade silicone sealants which can provide several benefits in this application:

Neutral Cure – no corrosive by-products

High Strength – suitable for large heavy cells

Fast Curing – improves production times

Excellent Adhesion – provides excellent bond strength

No H&S issues

Matching products

① CV-709 Silicone Sealant for PV moudles