SV-8890 Two-component Silicone Structural Glazing Sealant from China Manufacturer

Short Description:

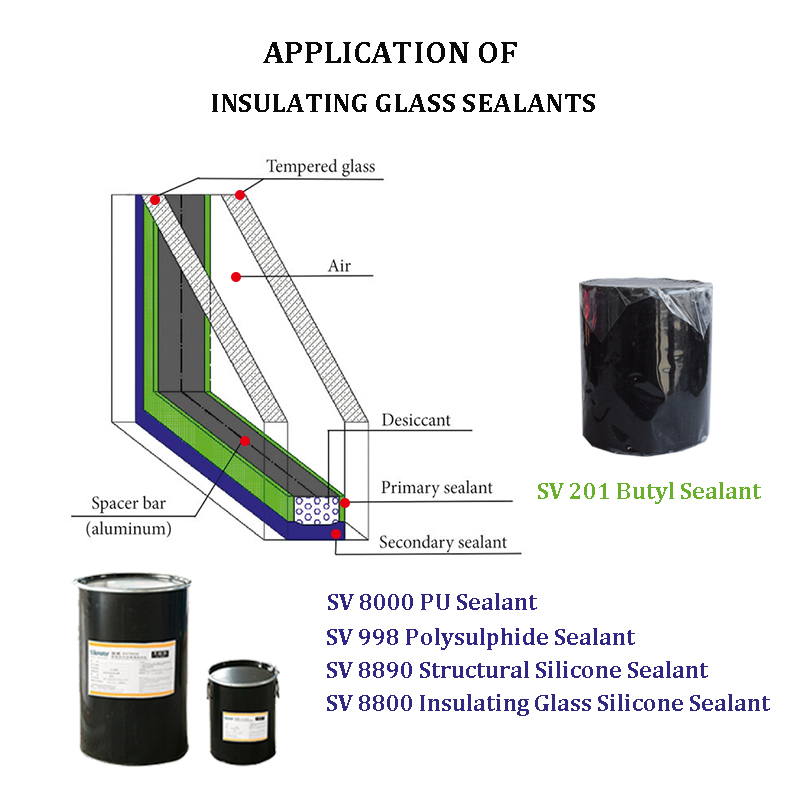

Description Two-component silicone insulating glass sealant is neutral-curing insulating glass secondary sealant with structural capabilities. The product formulation utilizes its high modulus and high strength properties to meet the requirements of insulating glass assembly. With its high modulus at short elongation it is especially designed for air- and noble gas-filled IG-units.

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for SV-8890 Two-component Silicone Structural Glazing Sealant from China Manufacturer, We will wholeheartedly welcome all clients in the industry both at home and abroad to cooperate hand in hand, and create a bright future together.

Description

Two-component silicone insulating glass sealant is neutral-curing insulating glass secondary sealant with structural capabilities.

The product formulation utilizes its high modulus and high strength properties to meet the requirements of insulating glass assembly.

With its high modulus at short elongation it is especially designed for air- and noble gas-filled IG-units.

Key Features

1. Economical joint sizes in high strength IG application

2. Suitable for gas-filled triple glazed units and gas-filled double glazed units

3. Adjustable working time

4. Outstanding adhesion to a wide range of substrates including coated and reflective glasses, aluminum and steel spacers, and a variety of plastics

5. Low water absorption

6. High modulus which limits the stress on the primary sealant and makes it particularly suited for gas-filled insulating glass units

7. Excellent temperature stability: -50°C to 150°C

8. Non-corrosive cure

9. Fast curing time

10. Outstanding resistance to ozone and ultraviolet (UV) radiation

Basic Application

1.Glass, stone, marble, granite, aluminum curtain wall and glass daylighting roof and metal structural engineering structural adhesive seal;

2.Insulating Glass of the second seal

3.Many other building and industrial applications

Technical data sheet

| Test project | Unit | value |

| Flow, sagging or vertical flow | mm | 0 |

| Operating time | min | 20 |

| surface drying time(25℃,50%R.H.) | min | 40-60 |

| Durometer Hardness | Shore A | 20-60 |

| At 23 ℃ maximum tensile strength elongation | % | ≥100 |

| Tensile strength(23℃) | Mpa | 0.9 |

| Tensile strength(90℃) | Mpa | 0.68 |

| Tensile strength(-30℃) | Mpa | 0.68 |

| Tensile strength(flooding) | Mpa | 0.68 |

| Tensile strength(flooding - ultraviolet) | Mpa | 0.68 |

| Bond damage area | % | 5 |

| Thermal aging(thermal weight loss) | % | ≤5 |

| Thermal aging(crack) | No | |

| Thermal aging(efflorescence) | No |

Certification

GB 16776

Color

Component A(Base) - White, Component B(Catalyst)- Black

Package

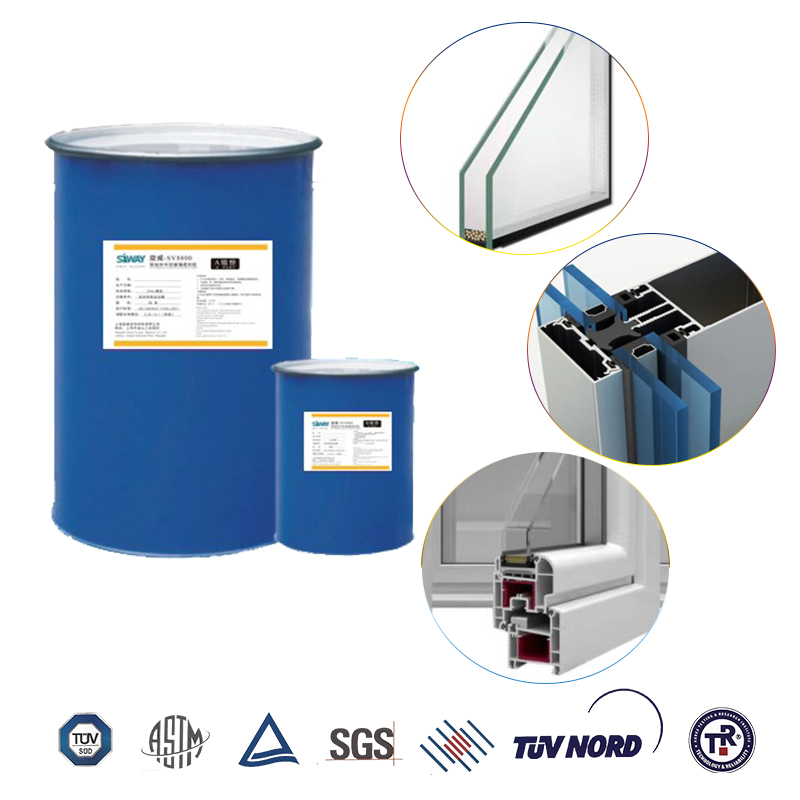

1. Component A(Base): (190L), Component B(Catalyst) (18.5L)

2. Component A(Base):24.5kg (18L), Component B(Catalyst): 1.9kg (1.8L)

Shelf life

12 months

Note

If you want the TDS or MSDS or other details, please contact with our sales person.

Surface Preparation

Clean alljoints removing all foreign matter and

contaminants such as oil, grease, dust, water, frost, old

sealants, surface dirt, or glazing compounds and protective coatings.

Mixing and Dispensing

To obtain the optimal performance of SV 8890,it is recommended that base and curing agent

thoroughly mixed using an airless two-part silicone dispensing

machine.

SV 8890 should be mixed at a ratio of 9:1~11:1 base to curing agent by volume or 11:1~14:1 base to curing agent by weight.

Lot matching of SV 89base to curing agent is not required. Before use, it is recommended that curing agent be fully stirred to ensure the homogeneity of all components

The construction application

In order to achieve the best physical properties SV-8890 silicone sealant structure should be the main agent and curing agent with airtight hybrid system. SV-8890 applies to general a two-component silicone rubber mixing machine on the market. Whatever mixing by hand or with a hand mixer will not bring a satisfactory effect, that is because mixture once joined the air would make its original nature changed.

SV-8890 silicone structural sealant without lot number.

SV-8890 silicone sealant structure of curing agent must first stir before use to avoid in the process of transportation may produce precipitation phenomenon.

Due to the curing agent could react with moisture from the atmosphere, not exposed to the air for a long time. SV-8890 silicone sealant structure of main agent and curing agent in the weight ratio of 12:1 (volume ratio of 9.1 :1). The user can change itself

Total combined ratio than 10:1 ~ 14:1 (volume ratio of 7.6:1 ~ 10.6:1) adjusting coagulation time. Within the scope of the mixture of sealant, its original characteristics there will be no significant change. But if the humidity of the air or omit, will influence the period of testing time and the time required to form a bond.

To get the right mix ratio, please contact SIWAY or mixing machine manufacturer.

Must be used immediately after turning sealant tool to press it gently into the interface and finishing, to ensure that it can completely within the bonding at the interface on the surface, resulting in better effect. Before shutdown, please only use the main agent into the mixer and the conveying pipe, and using the main agent to wash it. This will prevent sealant cause blockage in the internal curing.

To learn more about tao SV-999 silicone structural sealant of detailed information,Please contact local zhijiang company representative or designated agent. Our lab and technical staff ready to provide assistance.

Not curing sealant is absolutely not allowed with an abrasive surface, such as polished marble, metal or glass contact, because these extra sealant can not use organic solvent completely removed, so the surface must be covered, or in the construction of the sealant take extra care to prevent sealant come into contact with the surface, it will leave a layer of thin film on the surface, which will affect the base material peculiar and beautiful surface. If in the case of do not pay attention to not curing sealant and interface of adjacent non porous material surface contact, necessary before the sealant has not been solidified, using toluene, xylene and methyl ethyl ketone solvents to remove, when using flammable solvents, shall comply with the special attention.

Surface cleaning

All retained at the interface and assembly of rabbet residual moisture, dust, oil, paint, travel-weary sealant, fittings and protective coating completely removed.

Metal, glass and plastic surface solvent must be applied in accordance with the method of two pieces of cloth to wipe clean. No matter which method must with a piece of oil free, and not to take off the cloth with soft nap of clean cloth, with solvent swabs again and again with another piece of clean cloth to wipe off the residual solvents. Detergent or soap water cleaning method is not appropriate.

primer

Use SV-8890 silicone sealant structure generally don’t need a primer, but if the test report need to use primer bonding, with clean before get sealant in an excuse not to take off the velvet cloth will primer apply a thin layer on the surface and stay dry dry solid. Before it becomes sealant required test to determine whether need primer.

Cover and repairing interface

Near the interface parts need to be covered, in order to ensure the sealing line is perfect in good working order. Don’t let the cover contact with the tape will hit the surface of the sealant. Glue is completed, in front of the seal has not yet been crust, must adjust immediately, after the completion of the renovation work, cover tape shall be immediately clear.

Glue machine clean

When it is completed should be cleaned immediately to the main agent or in an appropriate solvent cleaning glue gun. Such as glue gun head in case of curing structural adhesive, is in the right